Specialising in ship applications, supply technicians DREWS Marine, with headquarters at Billbrookdeich in Hamburg, has primarily relied on the expertise of compressor specialist BITZER for over ten years. Whether for use in river cruise ships, in research ships or in top-class yachts: for the production of innovative refrigeration and air-conditioning systems, the companies from northern and southern Germany cooperate closely with one another. The refrigeration compressors are already in use in a total of 25 vessel classes for the shipping service provider founded in 1946. In current projects, too, the provider of marine air-conditioning and refrigeration systems trusts in the sustainable solutions from BITZER. The recipe for success: a long-standing partnership on a level playing field.

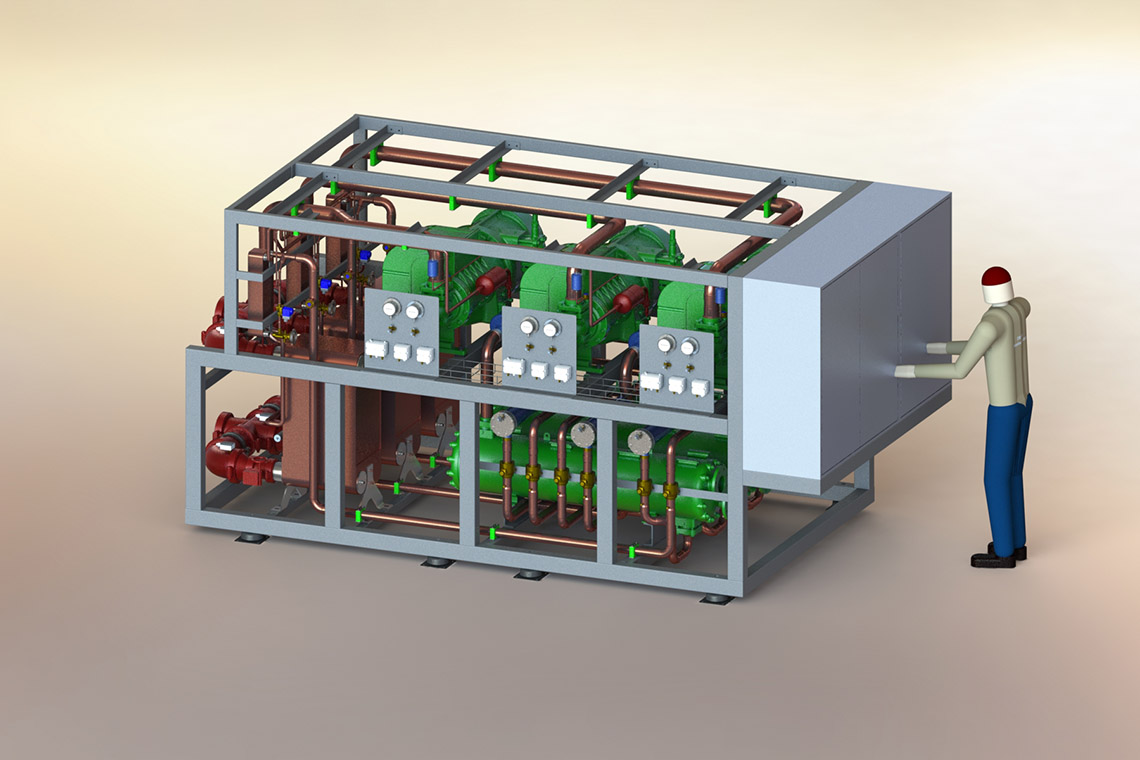

‘At sea, one thing is crucial: trust. You have to be able to trust in your own abilities, as well as in the technology. Who wants to find out after they’ve set off that their food has gone off because it wasn’t reliably cooled? Or that the air-conditioning systems are out of order?’ asks Marcel Wolter, Project Manager Refrigeration at DREWS Marine. So as to prevent failure, up to four compressors from various series are used per system. In the process, the adaptation to the particular structure of the ship is especially crucial because the air-conditioning technology has to fit with the individual requirements of customers. ‘For a cruise ship with many passengers, we need a different solution than for a container ship. Irrespective of this, one thing remains the same: the quality of the technology. This is crucial for a successful partnership.’

Efficiency meets performance

In system construction for river cruise ships in particular, DREWS Marine demonstrates a great deal of experience. The ships have to be compact and as light as possible in order to pass safely through the narrow turns of the Danube or the Rhine. This is also true of the CSVH screw compressors from BITZER, which also have to deliver high performance with a compact size. ‘This is precisely where we can rely on BITZER screw compressors. What’s more, they offer real savings in terms of space and weight. When it comes to the construction of air-conditioning systems, we primarily use screw compressors from the CSVH series,’ explains Marcel Wolter.

The models within the CSVH series are frequency-regulated and extremely energy-efficient. The semi-hermetic screw compressors have a modern rotor profile and possess durable pressure-released bearings that were specially developed by BITZER for a high speed range. The intelligent compressors have a sophisticated oil management system and work extremely energy-efficiently both in the high and low speed ranges. This is important because river cruise ships are required to activate an energy limit in harbours, which can lead to a reduction in cooling capacity in air-conditioning systems, for example. ‘A major problem is that the reduction in capacity is not only dependent on the ship’s crew, the passengers or the freight on board. Rather, the shore connection cables affect the amount of energy. Good efficiency is therefore doubly important in using the available resources optimally,’ adds Wolter. ‘Air-conditioning systems must therefore adapt to the local circumstances in the shortest possible time.’

Reliably prepared for any challenge

Thanks to flexible compression control, the compact powerhouses are ideal for supplying the required capacity for the long river cruise ships. ‘Depending on the concept, we use six to seven compressors on river cruise ships. Because the projects only rarely consist of several identical river cruise ships, the number and construction of the compressors vary here,’ says Wolter. It is fortunate for the contractor that BITZER is the only manufacturer in the world to make all primary types of compressor: reciprocating, screw and scroll. The large product portfolio allows the long-standing Swabian company to offer the right solution for almost any application.

‘For more than ten years, we have primarily relied on compressors from BITZER. The support in engineering, the outstanding quality of the products and the high operative reliability have won us over,’ sums up Marcel Wolter.

CSVH screw compressors – safe to use with simplified installation

The semi-hermetic CSVH screw compressors with integrated frequency inverter (FI) demonstrate the innovative strength of BITZER. The combination of proven CSH screw compressor mechanics and new features such as flexible frequency adjustment and automatic Vi control allow the intelligent screw compressors to work even more efficiently. The CSVH models can show off their full potential when used in air-cooled condensers and work in a wide range of control from 16 to 100 per cent.

In addition to the considerably improved ESEER/IPLV and SCOP values, the CSVH series is impressive with its compact and light construction. With a displacement of up to 1,156 m3/h, the compressors are real powerhouses in spite of their small size, and are reliably impressive under a high part-load in particular. In order to guarantee maximum security even in the high speed range, the CSVH series offers comfortable operation monitoring alongside integrated sensors for compressor protection. Using the BEST software (BITZER Electronics Service Tool), users have all operating parameters at a glance effortlessly.

HSN/HSK screw compressors – robust all-rounders for provisions refrigeration

Whether as an individual compressor, parallel compounding or for air-conditioning and medium temperature application, the semi-hermetic HSK screw compressors from BITZER are real all-rounders. Thanks to a large-volume suction gas-cooled built-in motor, the compressors work at an especially high level of efficiency. This is made possible by the multilevel capacity control, electronic protective devices and automatic start unloading. On top of this is the economiser operation, which improves both the cooling capacity and the system efficiency level for medium and high pressure ratios.

The HSK screw compressors are available in a total of 23 different model sizes and offer displacements of 84 m³/h to 535 m³/h (at 50 Hz). A considerable benefit of the entire series is the simple combination of various HSK models, for example for an increased air-conditioning requirement in ship applications. Thus, up to six screw compressors of the same model size can run in parallel. With the HSK series, BITZER also facilitates the connection of various compressor sizes in parallel. By using an additional compressor control, an extremely fine adjustment of the desired capacity is possible.

BITZER reciprocating compressors – the right solution for every challenge

The reciprocating compressors from BITZER have a key place in the marine field. How much cooling capacity is needed and which requirements the customer has of the reciprocating compressor varies from project to project. Whether semi-hermetic or open; frequency-regulated or 2-stage; two-, four-, six- or eight-cylinder compressors; halogenated or non-halogenated refrigerants: the right reciprocating compressor exists for every challenge.

Customers with exacting demands regarding sustainability and efficiency get their money’s worth with the reciprocating compressors in the ECOLINE series in particular. For years, they have been setting new technological benchmarks in the compressor segment, reducing the greenhouse effect and increasing efficiency. Among other things, this is possible because the compressors minimise pressure drops thanks to improved flow ratios and feature optimised valve plates. Specially adapted frequency inverters are also optionally available. Users thus achieve incomparably favourable seasonal energy efficiency and sustainably protect the environment.