Despite its 80 years of experience in refrigeration and air-conditioning and its exceptional market position, BITZER refuses to rest on its laurels. Alongside its core business, the company is also systematically expanding its portfolio of heat exchangers and pressure vessels. Andrea Serena, Product Manager of Heat Exchangers and Pressure Vessels at BITZER , explains the addition to the range: ‘Compressors are in our genes. But other components in the refrigerant circuit are also key for system efficiency and reliability.’ BITZER refers to heat exchangers and pressure vessels as ‘HEXPV’.

All BITZER HEXPV products are HFO ready. With the help of the BITZER software, users can design the long-standing company’s semi-hermetic compressors as well as condensing units and heat exchangers with HFC/HFO blends specifically to meet their requirements. That means that the compressor, the condensing unit or the condenser has undergone full qualification. The company therefore provides system suppliers with the opportunity to respond to end users’ demands and desires for sustainable, environmentally friendly refrigerants.

BITZER expands its product range

HEXPVs are key components of the refrigerant circuit. In order to fulfil the requirements of users and contractors, BITZER is planning to launch 16 projects devoted to product adjustment and expansion by 2021. A key quality characteristic of BITZER heat exchangers is the fact that they’re brazed. The benefits: they boast greater tightness and a more consistent coating than rolled heat exchangers.

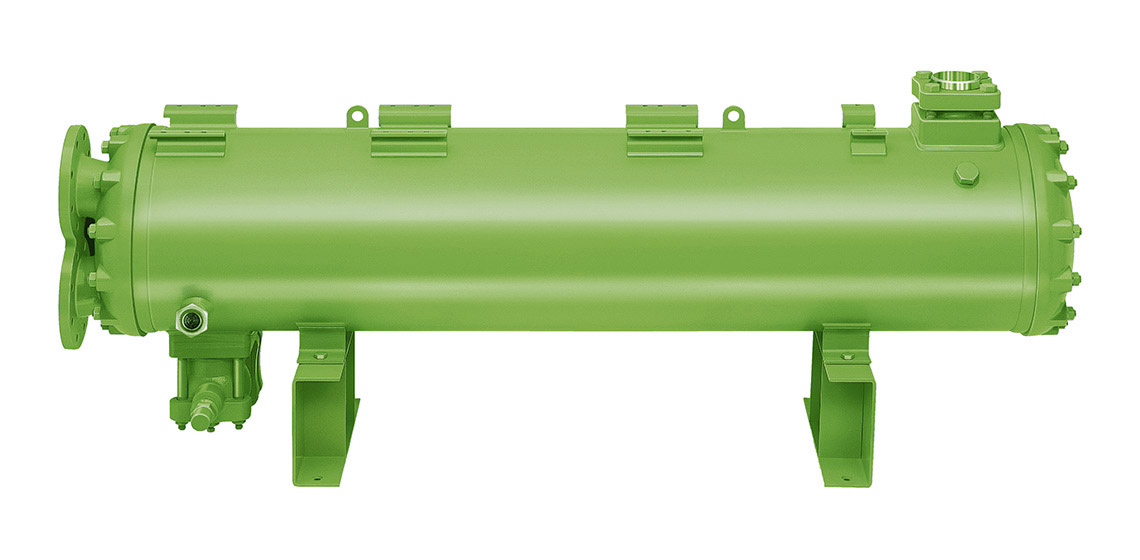

The acquisition of the shell-and-tube heat exchanger product group from Alfa Laval SpA in Alonte, northern Italy, represents a strategic step. Alfa Laval has decades of expertise in dry expansion evaporators, flooded evaporators and condensers for fresh and seawater applications with a capacity of up to 2,000 kW. ‘For BITZER, this is an important step in further developing the segment of heat exchangers and pressure vessels, as the evaporator technology manufactured in Alonte completes our existing product range. This acquisition makes BITZER the world’s largest independent manufacturer of shell-and-tube heat exchangers. Our aim is to become technology leader in this segment and offer the market the latest solutions. We’re therefore setting up a modern laboratory with highly qualified staff,’ says Gianni Parlanti, Board Member and Chief Sales and Marketing Officer of BITZER. The company is also expanding other HEXPV manufacturing sites. The idea is to produce in close proximity to the market in order to accommodate regionally varying user and legal requirements to the best of our ability.

‘With our project for heat exchanger and pressure vessel adjustment, we’re addressing our partners’ demand for flexible product solutions.’

Andrea Serena

Product Manager of Heat Exchangers and Pressure Vessels at BITZER

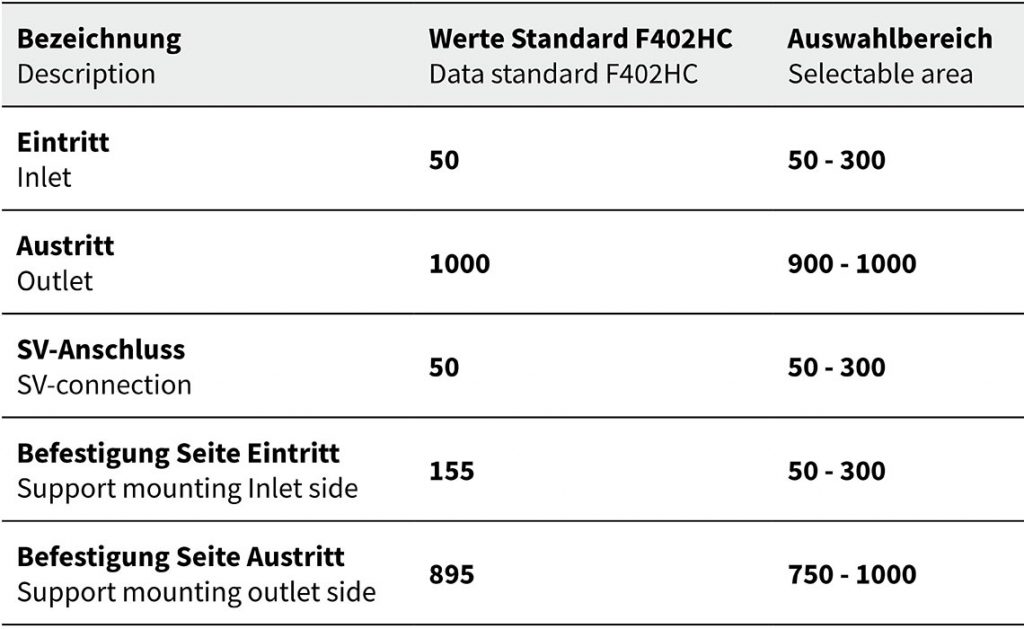

Customer requirements come first

Flexibility is the top priority when it comes to customer requirements, which is why BITZER offers them the choice between standard products and those tailored to their specific requirements. ‘With our project for heat exchanger and pressure vessel adjustment, we’re addressing our partners’ demand for flexible product solutions,’ says Serena. ‘Horizontal liquid receivers and water cooled condensers are just the beginning, with more of our products to follow.’ Up to five product components can be relocated from the standard position within a space established by BITZER, from the inlet and outlet refrigerant connections to the welded support legs. In this way, BITZER meets customers’ special requirements in terms of dimensions and functions. They can simply enter the new measurements either in the approval drawing in the document section of the BITZER website or using the BITZER software. And if you’re expecting longer delivery times, you’re going to be pleasantly surprised, as they’re similar to those of standard products.