To cool the seeds optimally and provide air conditioning in the offices, the Swiss refrigeration specialist Frigel AG installed a CO2 compound system from compact Kältetechnik in Dresden, which features BITZER compressors at its core.

Strong demand calls for effective seed cooling

As demand for organic seeds has skyrocketed recently in both the private and business sectors, Sativa grew so quickly since its establishment in 1999 that its production sites were ready to burst at the seams. As part of the design plan for the Chorb development zone that was approved by the town of Rheinau in Switzerland, the company therefore planned a new building for efficient seed storage, packing and shipping.

Ideal conditions for growing organic seeds

Deep down on the basement floors, seeds are stored at a constant temperature of 13°C – the necessary cooling capacity is equally small. The electrical energy needed to operate the coolers is generated by solar panels. Optimal seed storage conditions are a high priority for Sativa Rheinau AG.

The property is surrounded by groundwater, which guarantees stable ambient conditions in the storage rooms on the two basement floors all year round. The room temperature is maintained by various air coolers that are connected to a refrigeration system in a technical room on the first basement floor. Fabio Laib, Head of Engineering at Frigel, worked closely with compact Kältetechnik to design and build a refrigeration system that could maintain the constant temperature as well as a relative humidity of 30–35% throughout the storage area. This means that the climate-controlled seed rooms are cooled at the same time as the entire office complex is heated or air conditioned.

Future-proof refrigeration and air conditioning technology

As sustainability was a top priority in every aspect of this project – not to mention the increasingly strict environment legislation and regulations around the world – the planners paid particular attention to their choice of refrigerant. That is why the system uses R744 (CO2), a natural refrigerant with a GWP of 1 and excellent thermodynamic properties, to remain future proof for a long time.

A compound system to meet the highest standards

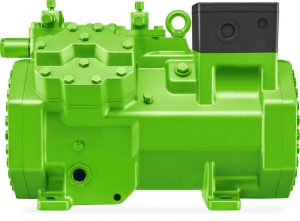

Seven BITZER ECOLINE compressors were installed to meet the challenging conditions of the project and the high energy efficiency requirements. The various temperature levels have been divided across two combined systems: An air conditioning system with three 4MTE-10K-40S compressors and a medium temperature / heat pump system with one 4PTE-7K-40S and two 4KTE-10K-40S compressors. The parallel compressor stage also features a 4JTE-15K-40P compressor. The parallel compressor works more efficiently with a lower pressure ratio.

© BITZER

Greater energy efficiency

The initially higher capital costs have a noticeable effect on energy efficiency and the electricity generated by the solar panels can be put to effective use. This reduces the electricity consumption of the company’s operations significantly. The medium temperature system has a cooling capacity of 68 kW at an evaporation temperature of -10°C. The air conditioning system is designed to have a cooling capacity of 95 kW at +5°C. Each of the lead compressors in the CO2 compound system is fitted with Invertek frequency inverters. Frequency inverters provide stepless capacity control over the lead compressors.

Natural heat use and precise temperature adjustment

Featuring a 110 kW heat recovery capacity, the gas-to-liquid plate heat exchanger is used to heat the floors and is fitted with an additional three-way valve so it can be adjusted depending on demand. The heat is extracted by a plate heat exchanger installed between the high-pressure flash vessel and the intermediate pressure vessel.

There is a constant flow of CO2 through the heat exchanger in order to guarantee constant air conditioning for the thermally activated building structures (TABS). These are polypropylene heat pipes set in cement. Fitted with these, the floors in a building actively radiate heat and the concrete acts as a thermal storage medium. This principle makes it possible to optimise the use of natural heat energy both ecologically and economically, and allows for precise temperature adjustment.

Additionally, a heat exchanger was installed in the liquid line after the intermediate pressure vessel due to the extended pipeline system and the extremely long pipeline paths. The refrigerant is subcooled separately to prevent the formation of flash gas. When it came to selecting a gas cooler, the company relied on the proven quality of Güntner. The special feature of this 180 kW gas cooler is its built-in condensing function that enables it to operate as an air source heat pump in winter. If the temperature in the hot water tank falls below 30°C, the three-way valve bypasses the gas cooler and another cooling position with a 70 kW evaporator capacity is activated. As parts of the building are underground, individual rooms have to be reheated in winter, especially if the temperature falls below 12°C for a given period of time. Activating the heat pump in this way makes it possible for water to reach a flow temperature of up to 35°C even in winter.

An energy-optimised complete system

The eight fans are controlled by a 0–10 V signal for stepless, energy-saving operation that is optimised based on the outside temperature. The complex system configuration was realised and put into production with Danfoss.

As one complete system supplies all the heating and cooling, the energy optimisation potential is enormous. Energy consumption can be reduced strategically when CO2 is used as a sustainable solution, which makes a valuable contribution to the company’s progress towards its climate targets.