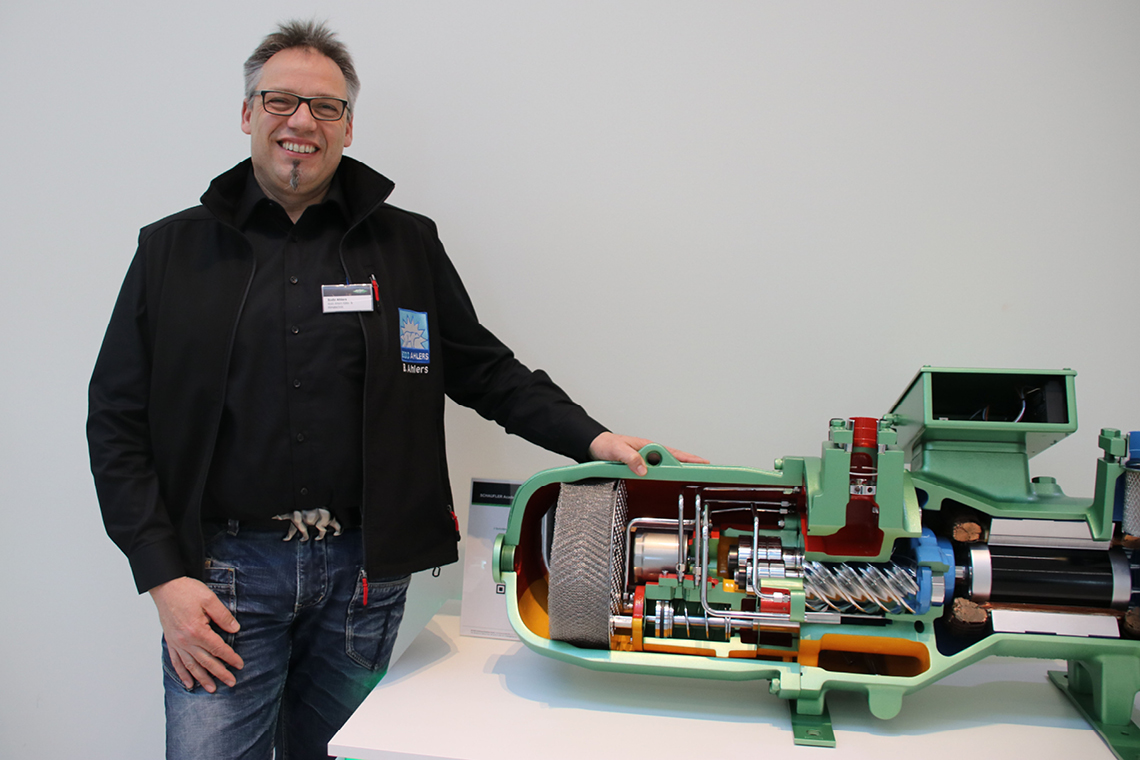

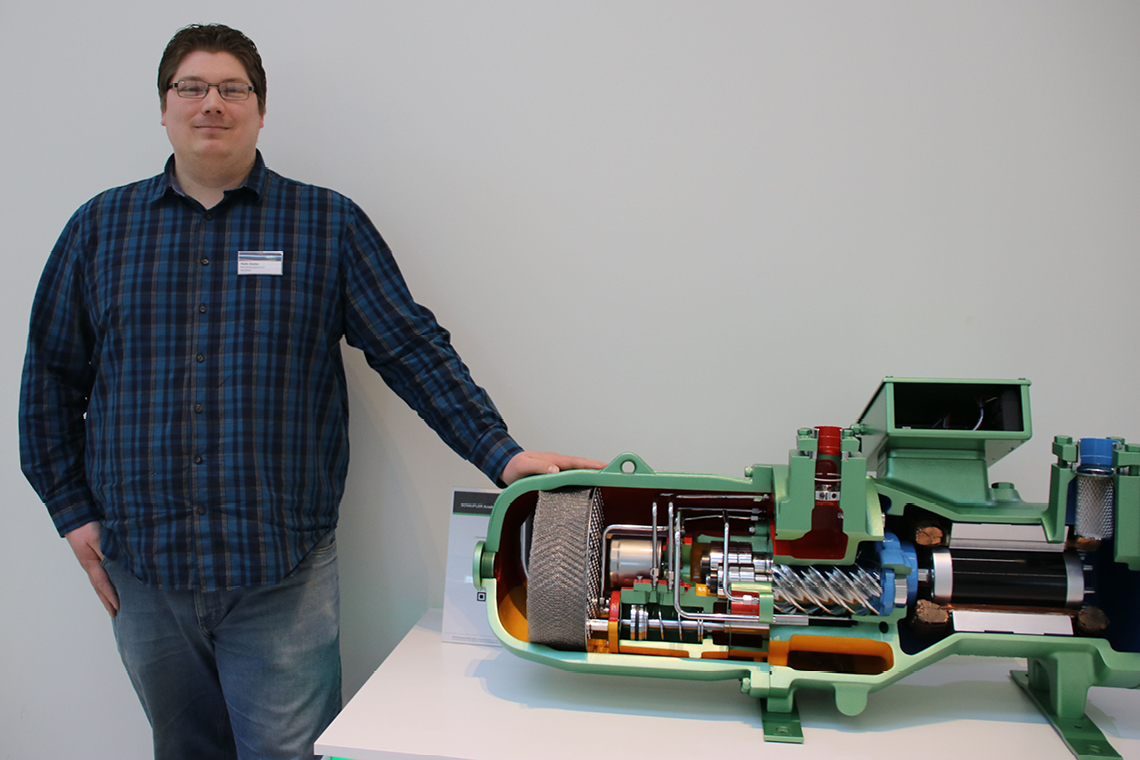

BITZER: Mr. Ahlers, you are the owner of Bodo Ahlers Kälte- und Klimatechnik in Wiefelstede, Lower Saxony, and you, Mr. Snater, work as a workshop instructor at the vocational training center for craftsmen in Bad Zwischenahn. Why are you taking part in the seminar?

Bodo Ahlers: I am taking part to find out more about the topics of propane and CO₂ and the conversion from old to new, alternative refrigerants.

Malte Snater: I work as a workshop teacher, i.e. I train apprentices in the workshop area. In order to be able to tell them new things, I have to continue my training. With me, the trainees always want to hear something practical, as they already know the theory from vocational school. Here at the SCHAUFLER Academy, the contents are taught in a very practical way for users, which I can later transfer well to “my boys and girls”.

This is the first seminar at BITZER for both of you. What did you particularly like?

Malte Snater: The seminar is very detailed with good, practical examples. We are given clear, good and profound information – but in such a way that even a “normal” refrigeration plant constructor can do something with it (laughs).

Bodo Ahlers: I think the scripts are very good. They are explained in a way that not only experts and teachers understand them, but also students. In the seminar, I got good information on how to produce or reproduce certain tests and experiments myself. Such examples are the best way to explain complex topics. The entire seminar is structured in a very practical way so that even an apprentice can understand it.

What do you take with you for your daily work?

Bodo Ahlers: The seminar takes away my fear of dealing with new refrigerants. I now know how to use them correctly and that with BITZER I have a partner at my side whom I can ask at any time. Here I get the feeling: “You have a large screw compressor system with a chiller? Just ask us. We won’t leave you alone in the rain.” I can call anytime and I’ll get help. It’s very comforting to know that.

Malte Snater: I now feel much safer with the new refrigerants. I know what they are susceptible to and what problems can occur. These challenges have been presented in a good and clear way, so that you get a few refrigerants that you can give to customers outside for several years – not just one or two.

Bodo Ahlers: Correct. The seminar enables me to assess for myself where and when I can use which refrigerant without falling into a hole or running into a wall and not being able to get anywhere.

Will you come again?

Bodo Ahlers: Absolutely. I can also well imagine sending one of my trainees to a seminar.

Malte Snater: Yes, I can definitely imagine it too. As a teacher, I have to train myself constantly anyway. The next thing I would be interested in would be training on CO₂ or ammonia. There is a need for training here, so that I can in turn better train the apprentices in the workshop

SCHAUFLER Academy – Upcoming Seminars

| 17-03-2020: BUS Training/DE | Overview page with further information |

| 18-03-2020: Frequency Inverter Training/EN | Overview page with further information |

| 23-04-2020: Hydrocarbons Training/EN | Overview page with further information // Direct link to the seminar (without overview page) |

| 01-04-2020: CO2 subcritical/EN | Overview page with further information // Direct link to the seminar (without overview page) |