Maastricht is a university city and one of the oldest cities in the Netherlands, located in the south-east of the country near the borders with Belgium and Germany. The city is home to more than 120,000 people and played host to the signing of the Treaty on European Union in 1992. In addition to the university with its 18,000 students, the city is also known for the adjoining university hospital Maastricht UMC+. It is the only centre in the Netherlands that carries out pre-implantation genetic diagnoses, which aim to identify serious genetic disorders in unborn babies such as Huntington’s disease and cystic fibrosis.

But high-tech medicine requires proper air conditioning in order to provide the necessary, often life-saving services. In 2016, the hospital managers approached BITZER partner Energie Totaal Projecten (ETP) in the Netherlands, as the heating and air conditioning system needed to be replaced. Marcel Kloowijk, Director at ETP explains: ‘Our recommendation to the hospital management was to use energy-efficient, high-temperature heat pumps, which provide both heating and air conditioning.’

Four heat pumps, one COP of 3.46

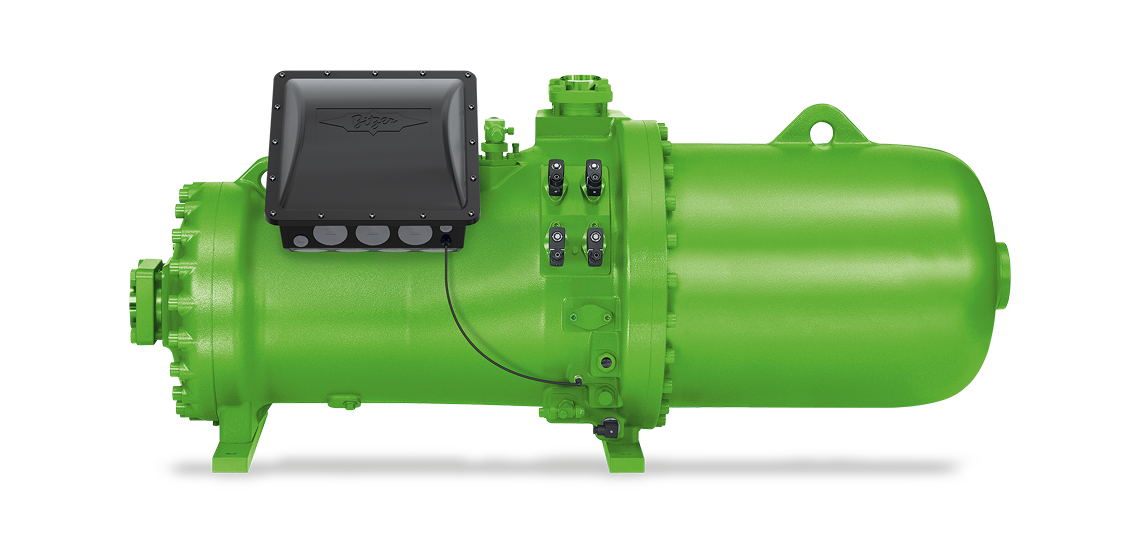

No sooner said than done. ETP has put its trust in proven BITZER quality for years and thus planned from the beginning to install four CSH9593 screw compressors in the heat pumps. Marcel Kloowijk says: ‘We opted for the large BITZER screw compressors because compressors with integrated oil circuit have dramatically simplified the project and because the CSH9593 is extremely efficient.’ And that is despite the fact that the screw compressors need to operate seamlessly in the low temperature range between 6°C and 11°C and in the heating range between 48°C and 65°C. Marcel Kloowijk adds: ‘We have used a special technology to get the most out of the compressors: a very low-energy process referred to as direct expansion.’

A combined liquid receiver and suction gas superheater increases the evaporation temperature, controls the superheater and protects the compressor from liquid slugging – all at the same time. The system’s asymmetric design, on the other hand, ensures a high capacity and minimal loss of suction gas pressure.

Space in short supply

The space available for the installation of the heat pumps in the existing power plant was very limited. Marcel Kloowijk: ‘We had to construct the heat pumps in such a way to ensure they would fit inside the small power plant.’ Another challenge was that high temperatures result in a very high oil carry over rate. But the ETP experts were able to overcome this challenge too. R134a is the refrigerant of choice, as it is the most suitable for the temperatures and for the system’s required capacity and efficiency. The refrigerant HFO1234yf is also suitable for the CSH9593 and could also be used. Marcel Kloowijk: ‘We are talking about system capacity of nearly 3,000 kW for air conditioning and more than 4,000 kW for heating. All the same, the system achieves a COP of 3.46, which the frequency inverters also enable at each and every individual screw compressor.’

The investment for the installed system has already paid for itself in two years. Thanks to outstanding energy efficiency, the hospital has reduced its CO₂ emissions by approximate 1,450 ton/year. Marcel Kloowijk adds: ‘This project is an excellent example of how effective collaboration leads to successful projects. We will continue to rely on the tried-and-tested products and effective collaboration with BITZER.’