‘The door opening was exactly 90 centimetres wide – during the project it had to be widened by 20 centimetres to a width of 110 centimetres,’ explains Mirko Bernabei, Beijer Ref OEM Segment Technical Director. Space is in short supply in the basement of the ABC Lavpris supermarket in Randers, Denmark, but not on the building’s ground floor, where several refrigerated display cabinets and cold stores needed to be cooled with precision. Robert Greisen, project manager at Vojens Køleteknik, adds: ‘After the first on-site inspection, it was clear that the lack of space for the refrigeration system would be one of the biggest challenges of this project.’

Limited space for lots of technology

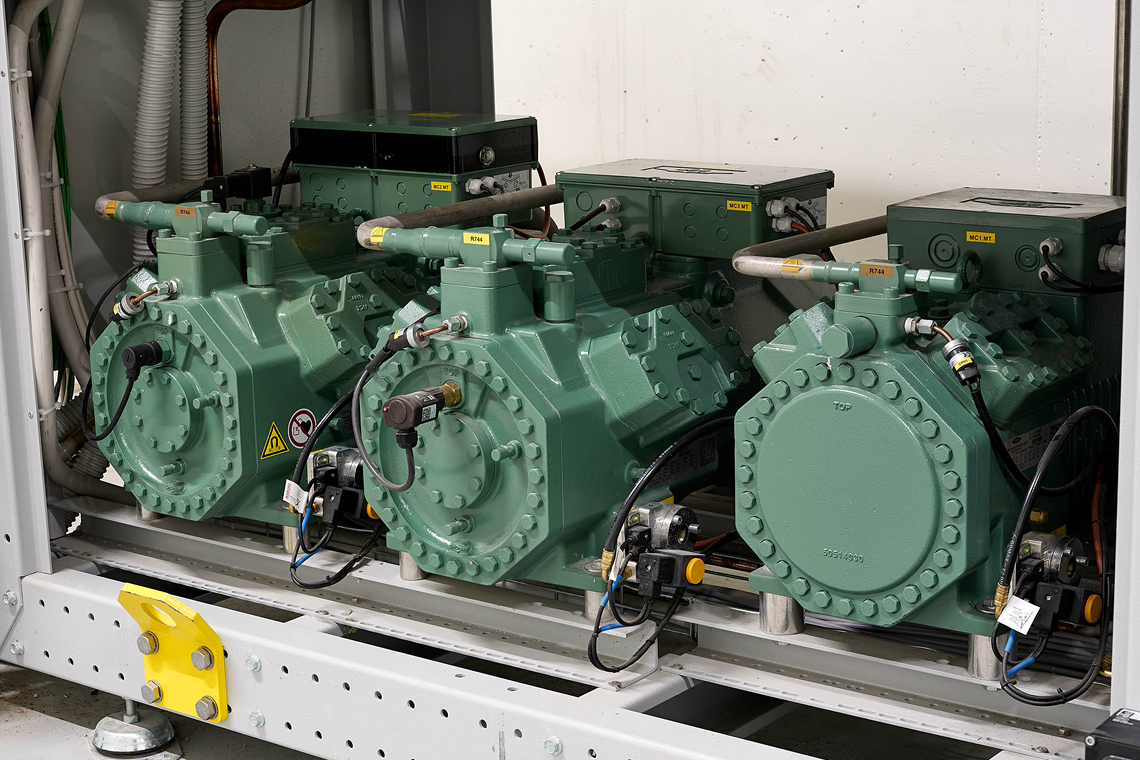

Randers, a port city in north-east Denmark, has just over 60,000 residents and is located in the region of eastern Jutland, some 40 km north of Aarhus. In summer 2017, representatives of the ABC Lavpris supermarket chain commissioned partners SCM Frigo and Vojens Køleteknik to optimise the refrigeration and heating system for the modernised supermarket. The two companies can look back on 40 years of expertise and have been successfully working together for 13 years. The technical requirements soon became clear: the refrigeration system needed to offer a cooling capacity of 129 kW in the medium temperature application with an evaporation temperature of –9°C and a cooling capacity of 48 kW in the low temperature application with an evaporation temperature of –35°C. ‘We made the decision to break down the system into two parts and reduce the number of installed compressors to the absolute minimum,’ says Mirko Bernabei. Based on extensive experience and years of successful collaboration, the project managers opted for BITZER reciprocating compressors, which are operated with CO2 refrigerant. ‘We’ve been using BITZER CO2 compressors for nearly 15 years now and are well aware of the unbeatable quality. In this supermarket system, we’re now using the tried-and-tested ECOLINE semi-hermetic reciprocating compressors. In the medium temperature application, we installed three compressors for transcritical CO2 applications: an OCTAGON, ECOLINE and ECOLINE+ with IQ module and VARISTEP. In the low temperature application, we have three semi-hermetic reciprocating compressors for subcritical CO2 applications,’ Mirko Bernabei adds. Still, the door opening had to be widened by 20 centimetres to a width of 110 centimetres.

Intelligent planning with intelligent components

But it didn’t end there: SCM Frigo also put its trust in the BITZER IQ module and VARISTEP technology from the beginning. ‘The IQ module makes all compressor information accessible. Access via the BEST software also offers a decisive advantage in terms of maintenance. And because we only have three compressors each in both the medium and low temperature application, the VARISTEP control was key to ensuring optimal system operation.’ Another benefit of the BITZER IQ modules: the compressors are delivered pre-mounted. A priceless advantage for the SCM Frigo and Vojens Køleteknik project managers, as it makes their work so much easier. ‘All in all, it’s safe to say that the system can be controlled with greater precision based on requirements, thanks to the BITZER IQ modules and the intuitive BEST software. This in turn has a positive impact on operating costs,’ says Mirko Bernabei.

Exploiting the system’s excess heat

‘Another special system feature is heat recovery,’ says Robert Greisen. It’s used to heat the supermarket, the flats above it and the industrial water for the flats. ‘The family-run ABC Lavpris company sells the refrigeration system’s additional excess heat as district heating, generating approximately €27,000 a year,’ Robert Greisen adds. A concept with a future: in addition to its existing 14 supermarkets, ABC Lavpris also plans to modernise additional markets and optimise their energy systems in the years to come. As such, the company founded in 1981 not only contributes to environmentally friendly refrigeration, but is also future-proofing jobs for its 550 employees.

Technical Data

| 1× OCTAGON for transcritical CO2 applications (4FTC-30K) | Lead compressor 1 Operated using a frequency inverter | CO2 refrigerant |

| 1× ECOLINE+ for transcritical CO2 applications (6DTEU-50LK) | Lead compressor 2 ECOLINE+ compressor including VARISTEP | CO2 refrigerant |

| 1x ECOLINE for transcritical CO2 applications (6CTE-50K) | Compressor 3 for demanding refrigeration requirements | CO2 refrigerant |

| 3× reciprocating compressors for subcritical CO2 applications (2DSL-5K) | Proven compressors of the SL series | CO2 refrigerant |

| Intermediate pressure vessel with 300 litres | ||

| Shell&Tube Heat Recovery 245 kW with water coming in at 30°C and out at 45°C | ||