In December 2019, the requirements for a new system for the freezing of fresh tuna came up at Chian Chen Fishing Port in Kaohsiung, Taiwan. For this system, the companies ETECO and Aking have successfully been working together with the support and products of BITZER. ETECO has already been a BITZER distributor in Taiwan for 30 years, whereas the contractor Aking has been a long-term BITZER customer for more than 20 years. It is the first project in Taiwan ever to incorporate the BITZER Digital Network, or shortly: BDN. Not to forget the other main protagonists: two BITZER ECOLINE reciprocating compressors with VARISTEP capacity control as well as the IQ module. The system has a total cooling capacity of 70 kW with a room temperature of –55°C in a total room size of over 261 square metres and a height of seven metres. The refrigerants in use are R507A and R23.

An ideal source

BITZER Digital Network is a digital infrastructure for customers and partners to manage their BITZER products both from an overall perspective and in every detail. One of its main key features is the uncomplicated access to as well as storage and management of all product- and application-related information, providing a simple solution to keep track of relevant user equipment. Calvin Hung, Sales Manager at ETECO, reports more on the reasons for opting for BDN in this special case: ‘We were lucky to get great support from our contacts at BITZER Hong Kong and the German BITZER headquarters. This was of great help to us, since we had never used the BDN before – but this was just the beginning! Basically, the BDN offers us all necessary data just one click away, which makes it all so convenient.’ Stephen Chan, Technical Manager at BITZER Hong Kong, adds: ‘It was important for our customer to be able to monitor and record the compressor operation, since it is all about food safety here. If something were to happen to the freezing system, all the fresh tuna would spoil. Therefore, it is a great advantage that thanks to the BDN, they can now monitor everything and are notified directly in case of anomalies with the system.’

Next-level teamwork

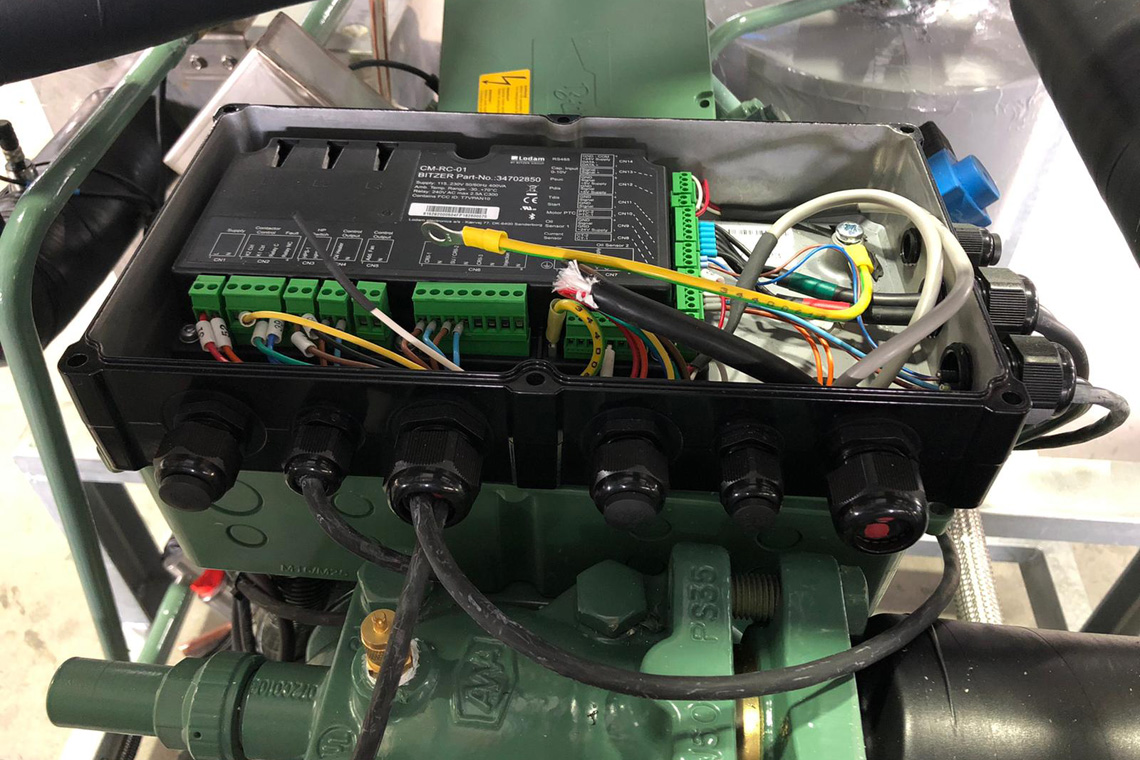

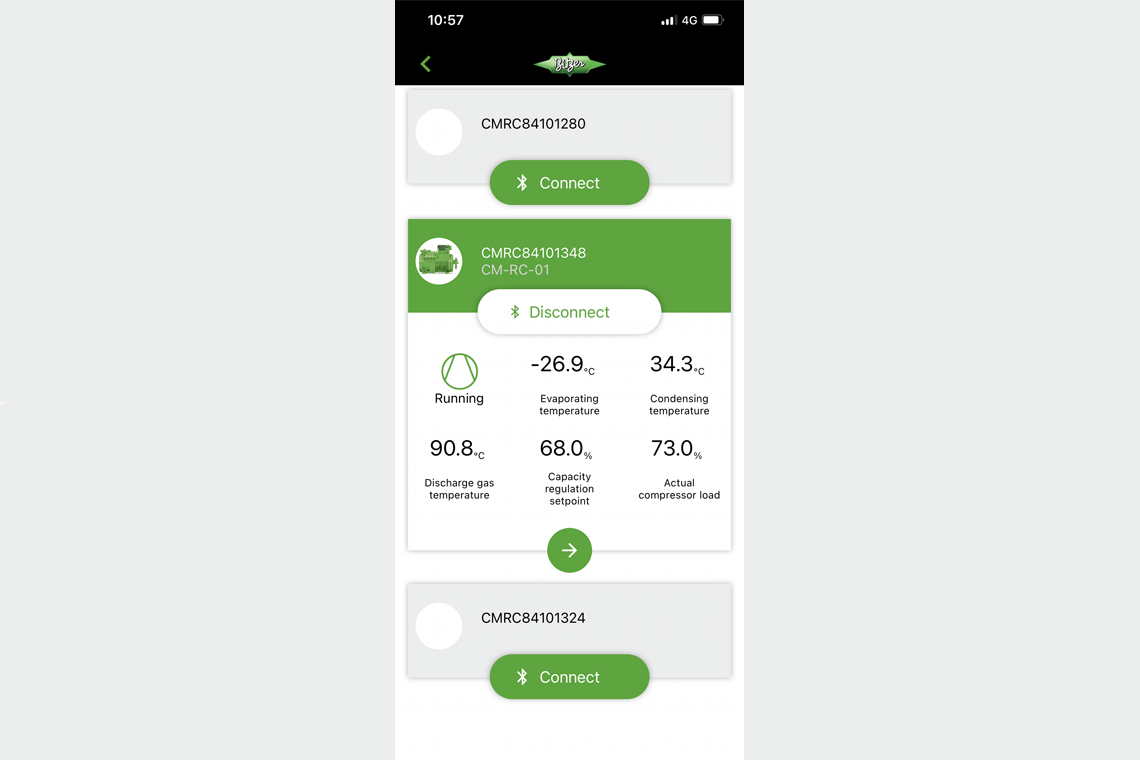

They are all perfectly connected: IQ module, VARISTEP capacity control and BDN. Calvin Hung remembers: ‘We chose the IQ module in combination with VARISTEP for this application because we wanted to maintain the high stage compressor at a constant pressure to be able to handle the different loads of low stage operation. Plus, we got easy access to the operating conditions using the Bluetooth interface with the BITZER BEST app on our mobile phones.’

The IQ module’s intelligence ensures optimum operation of the VARISTEP capacity control, which itself enables virtually seamless compressor operation with a refrigerating capacity of between 10 and 100 per cent. Furthermore, the IQ module is an ideal and reliable source of data for the BDN. The data from the module is transferred to the BDN through a preconfigured gateway. And everyone involved benefits from this perfect combination of BITZER solutions. The new tuna freezing system has been successfully running since May 2021.