They say that good things come in threes, which has been a fact for BITZER condensing units since April 2018 at the latest. Since then, BITZER customers have been able to choose between the easy to use new ECOLITE series and the proven LHE and ECOSTAR series. The ECOLITE condensing units cover the mid-capacity segment between the standard LHE series and the premium ECOSTAR series.

With the seven air cooled ECOLITE models, BITZER has developed an all-new series designed for display counters, small shops, cold stores and other applications. Constructed to offer a simple solution for challenging applications, the series covers the mid-capacity range between the LHE and the ECOSTAR solutions. The three small LHL3E and four large LHL5E ECOLITE models feature the proven ECOLINE reciprocating compressors and, thanks to the VARISTEP mechanical capacity control, flexibly adjust between 50 and 100 per cent to meet operating requirements. The four LHL5E models even offer optional capacity control between 10 and 100 per cent.

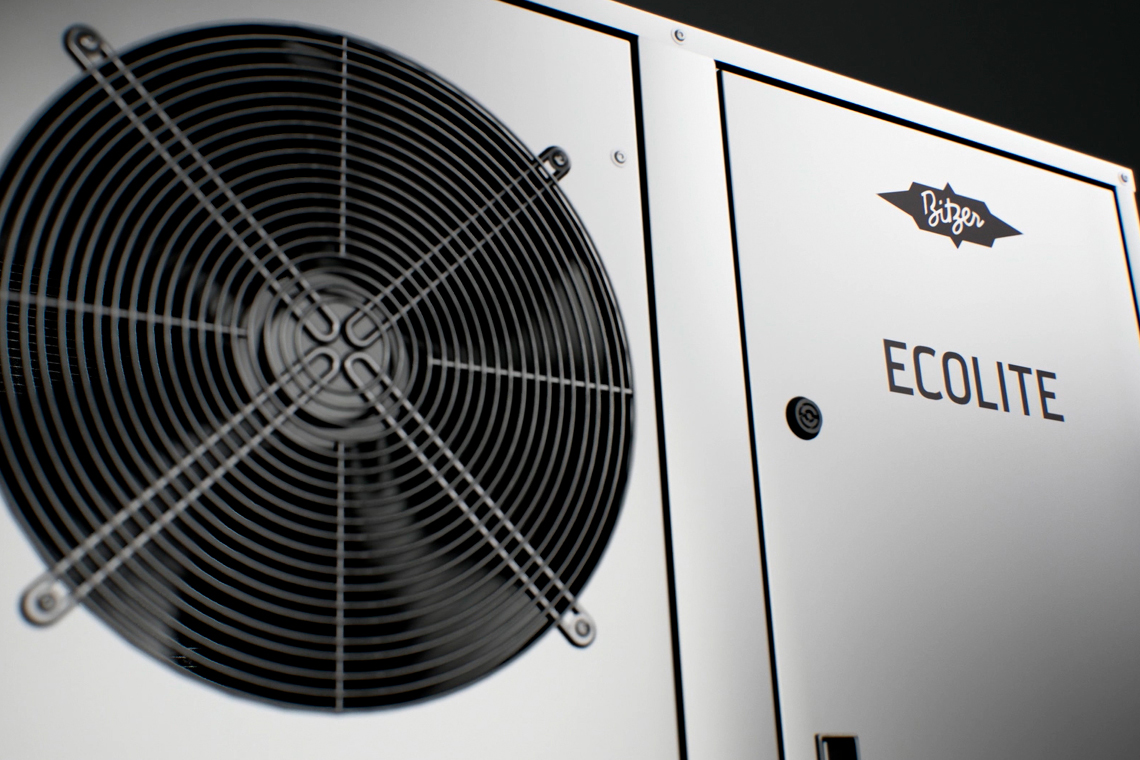

ECOLITE – wide application range, simple commissioning

All seven ECOLITE condensing units are designed for low and medium temperature applications and accommodate a wide application range, from 1.5 kW to 5 kW in the low temperature refrigeration range and from 3.5 kW to 16 kW in the medium temperature range. The entire series is easy and fast to commission thanks to the plug-and-play concept and boasts a user-friendly control unit with display as well as an emergency operation feature. The operating parameters can be adjusted, monitored and prepared as data logs using the BEST software.

ECOLITE condensing units are also Ecodesign-compliant and designed for operation with low-GWP refrigerants like HFO A2L refrigerants, which are now approved for the LHE series. Because the condensing units have system-optimised components and a highly efficient condenser, they only require a small refrigerant charge. While the LHL3E condensing units have one fan, BITZER has equipped the LHL5E models with two.

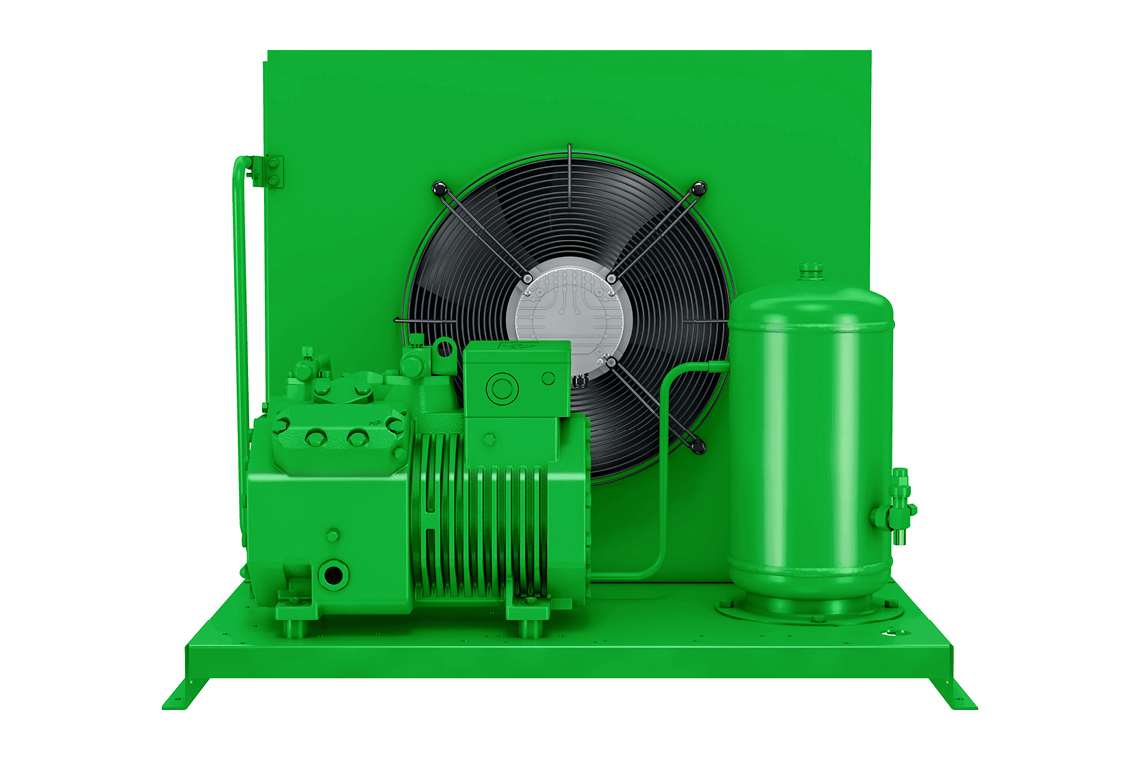

LHE – setting high standards

The standard series of BITZER condensing units is called LHE and is setting capacity and quality standards in the global refrigeration industry. The entire series can be used for refrigeration applications and operates with many refrigerants, including environmentally friendly low-GWP refrigerants such as refrigrants of the A2L safety class. There’s also the fact that, thanks to its efficient mini-channel condensers, the series can get by with a small refrigerant charge.

The heart of the condensing units is an ECOLINE reciprocating compressor, which is integrated as standard and works with the modern EC fans to reduce energy consumption and thus operating costs. LHE condensing units also fulfil the requirements of the Ecodesign Directive and thus offer users planning security over the long term. BITZER has generously equipped the series with an extensive range of accessories, two-stage designs and models for ambient temperatures exceeding 43 °C. System operators also benefit from the low installation, operating and maintenance costs.

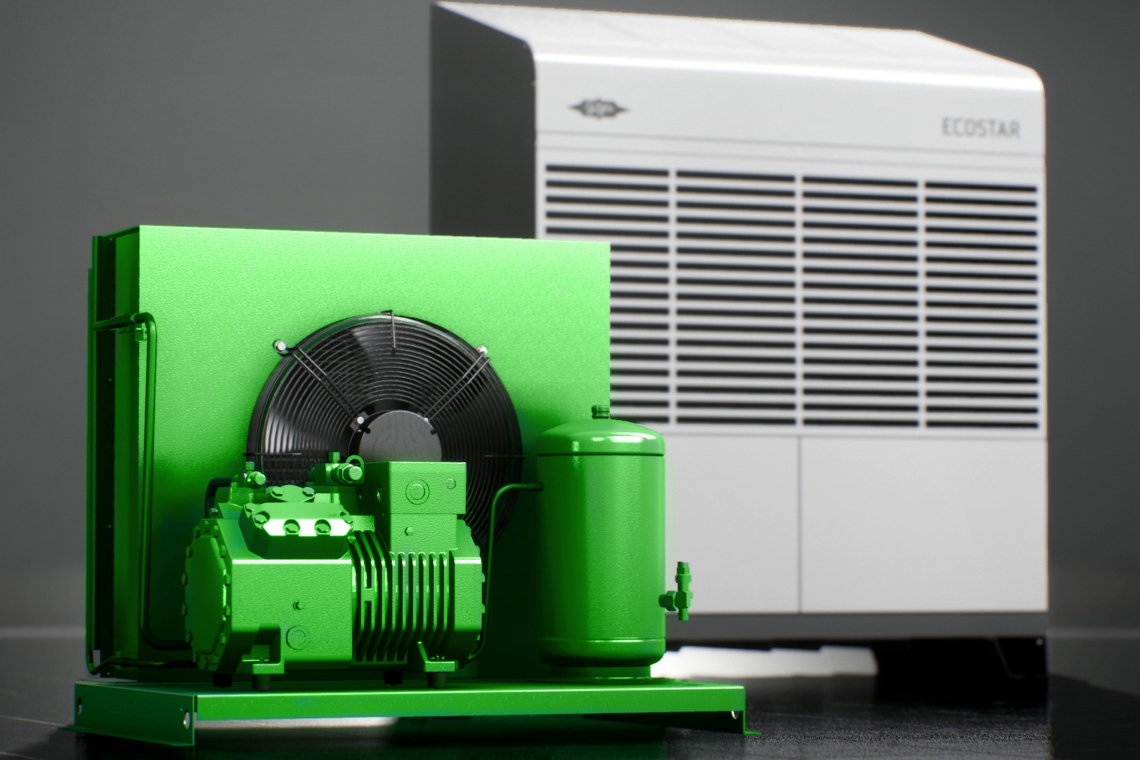

ECOSTAR premium quality

Extensive equipment, unique software functions and maximum efficiency: the BITZER ECOSTAR condensing units represent a benchmark in their product group and demonstrate what premium means. The entire series is simple to commission thanks to the plug-and-play concept and its fans can be operated in ECO and low-sound modes. A Bluetooth interface for wireless communication with the BEST software is also integrated into the ECOSTAR models as standard. The equipment also includes a web server for remote access as well as ECOLINE VARISPEED reciprocating compressors. Integrated as standard, the capacity control enables the best results in full and part load operation.

Designed to solve real challenges: ECOSTAR condensing units

ECOSTAR condensing units are designed for demanding operating conditions. The entire series is equipped with an emergency operation feature. The winter start feature, refrigerant injection for extreme operating conditions, oil recovery operation and wet-operation detection also ensure safe and optimal operation for any conditions imaginable. Up to four ECOSTAR condensing units can be combined to accommodate master/slave operation. The low noise level and energy consumption round off the premium package of the ECOSTAR condensing units to perfection.