Authors: Florian Simon, Oliver Javerschek, Julian Pfaffl, Julia Rojahn (Application Engineering, Rottenburg)

Case study: CO2 refrigeration system with ejectors in a fictitious distribution centre

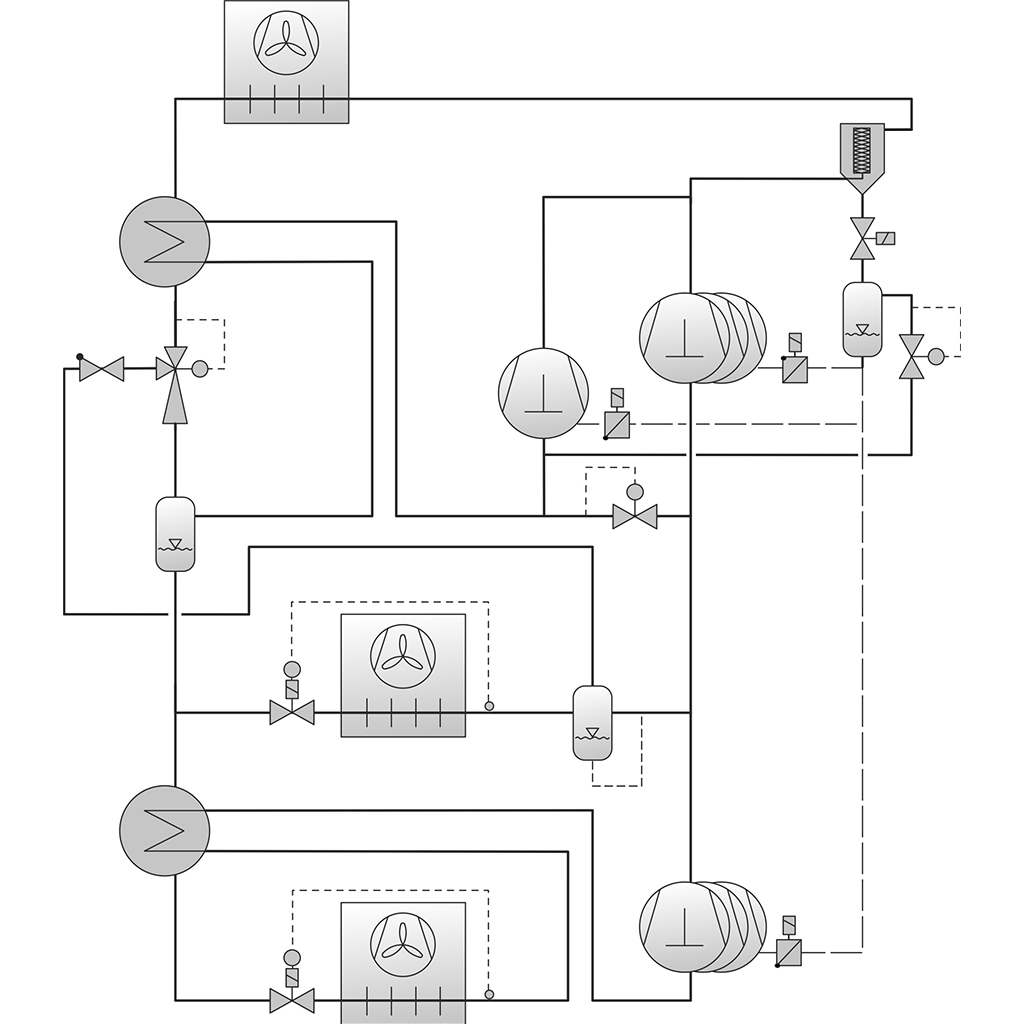

Simulations in the BITZER Software reveal the energy benefits for a fictitious distribution centre with 1,000 kW for medium temperature (MT) applications and 300 kW for low temperature (LT) applications. The adjustable ejectors enable operation as a high-lift or FGB system, with no additional high-pressure control valve necessary.

For full and part load operation, a distinction is made between five ambient temperatures (summer/winter) and ‘opened’ and ‘closed’.

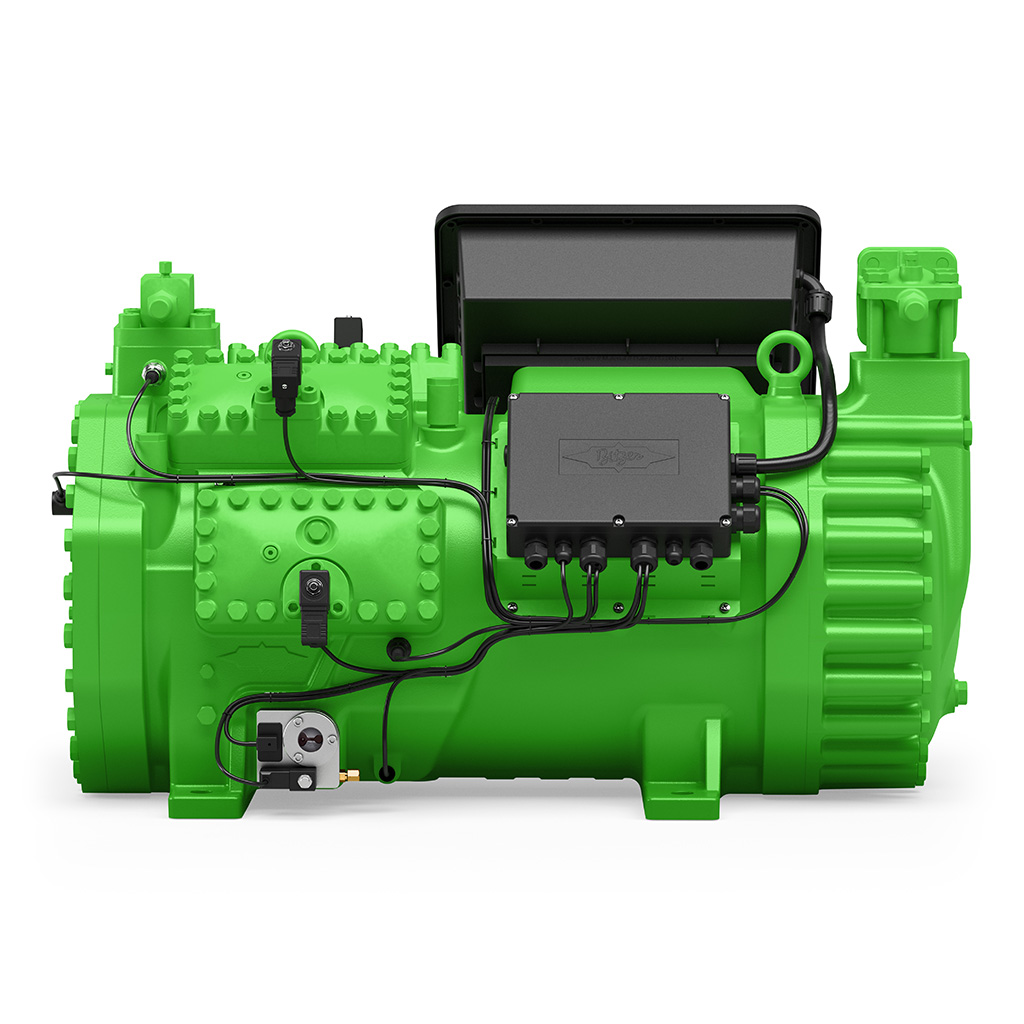

The optimal solution for full load (summer day with an ambient temperature of 37.5 °C, centre opened) is a system in transcritical operation with two 8-cylinder compressors in the MT stage, three 8-cylinder compressors in the parallel stage (each 8CTE-140K) and four 4-cylinder compressors in the LT stage (one 4TME-20K, three 4PME-25K models). The lead compressor for each stage is operated with frequency inverter.

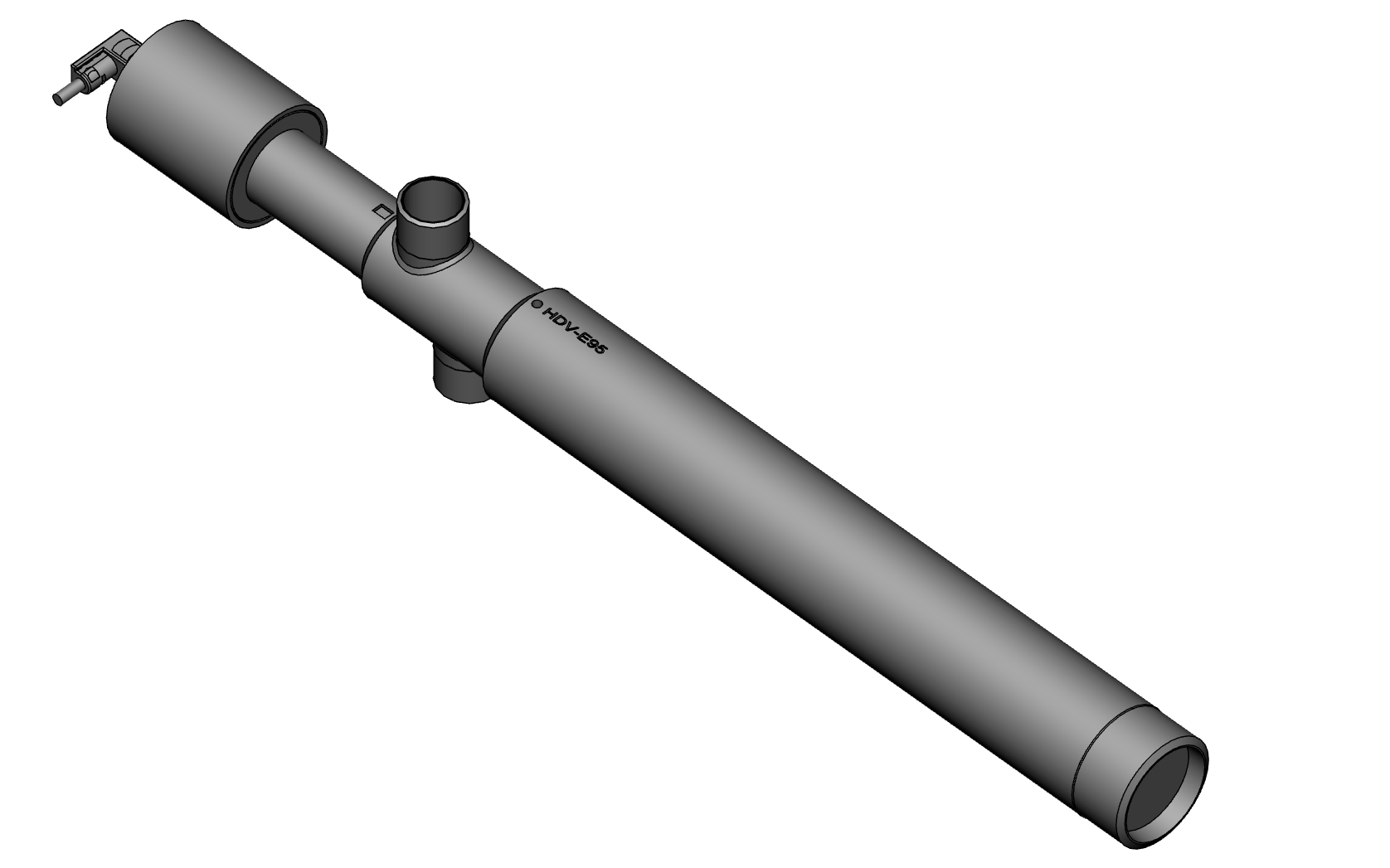

Of the five ejectors required (one HDV-E65, four HDV-E95 models), the HDV-E65 is throttled. A desuperheater is installed downstream of the LT compressors resulting in a MT discharge gas temperature of 149.5 °C.

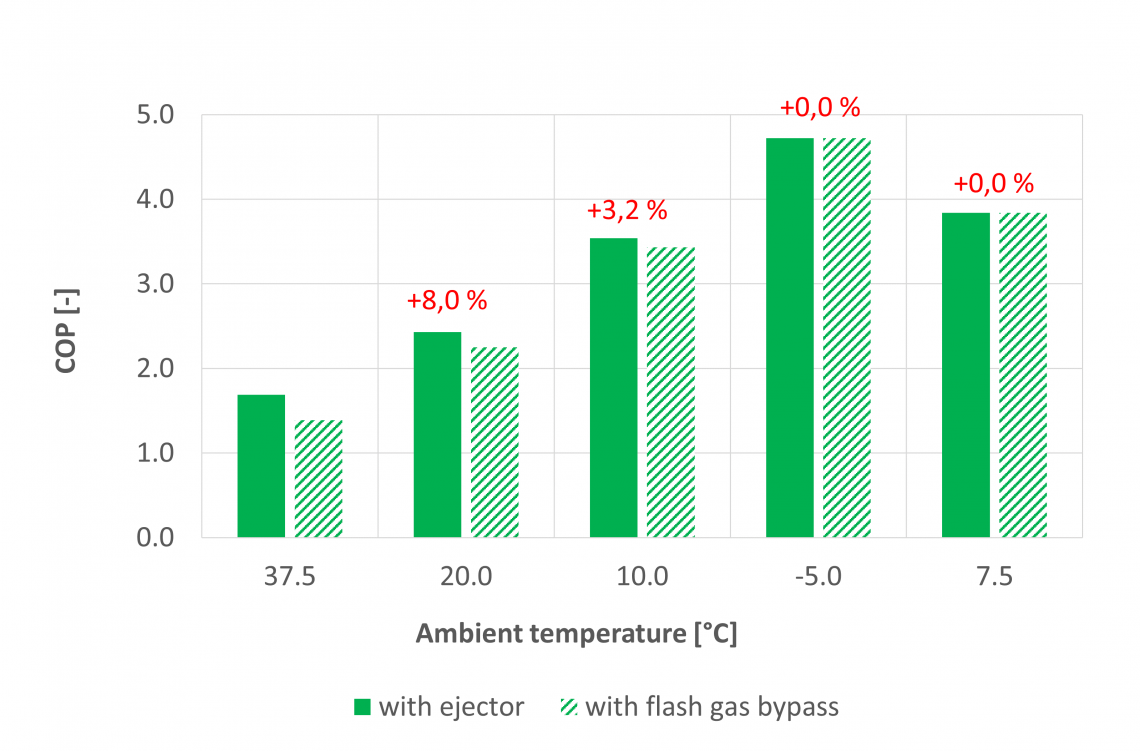

Increased COP thanks to ejectors

The calculated COP is 1.69 and therefore 21.5 % higher than that of a comparable FGB system. As the graphic shows, there is less of an energy benefit if the ambient temperature is lower, as there is less potential energy at the ejector input. The ejector-related relief in the MT stage and stress in the parallel stage diminish.

For the simulated operating conditions in winter (ambient temperature of 7.5 °C or -5.0° C °C), the potential energy at the ejector input is no longer sufficient for high-lift operation. The system is operated as an FGB system, whilst the ejector acts as a high-pressure control valve.

The design also shows that, for a mild winter day with the centre opened (MT load of 65 %, LT load of 70 % and ambient temperature of 7.5 °C), the system requires one more MT compressor than it does in full load operation, as operation with a parallel compressor is not possible. This can be resolved with a ‘swing compressor’, which can be operated as an MT or parallel compressor depending on the operating conditions.

In summary, equal attention should be paid to full and part load conditions.

In other words, it is essential to consider full and part load conditions if a CO2 refrigeration system is designed with ejectors. For example, the higher the ambient temperature is, the higher the pressure and the potential energy available at the ejector input will be – and therefore the higher the energy benefit of parallel compression (more significant increase in COP).