For decades, BITZER has been synonymous with the highest standards of quality in terms of efficiency, reliability and environmental friendliness. The refrigeration and air conditioning specialist works closely with its business partners all over the world to provide its customers with the product quality that they have come to expect from BITZER. As a driver of innovation in the sector, the company also views its suppliers as strategic partners. With this sense of perspective, BITZER is always able to realise innovative technology and materials whilst maintaining its own high standards of quality at the same time. This is possible because BITZER has established its BIPROS production system at all of its sites.

BIPROS – BITZER sets global standards

BITZER has developed its own production system in order to adhere to the same standards all over the world. BIPROS builds on the key BITZER principles of quality and customer orientation and ties them in with the objectives of the company, specific production processes and the most valuable resource of BITZER: highly qualified and committed employees.

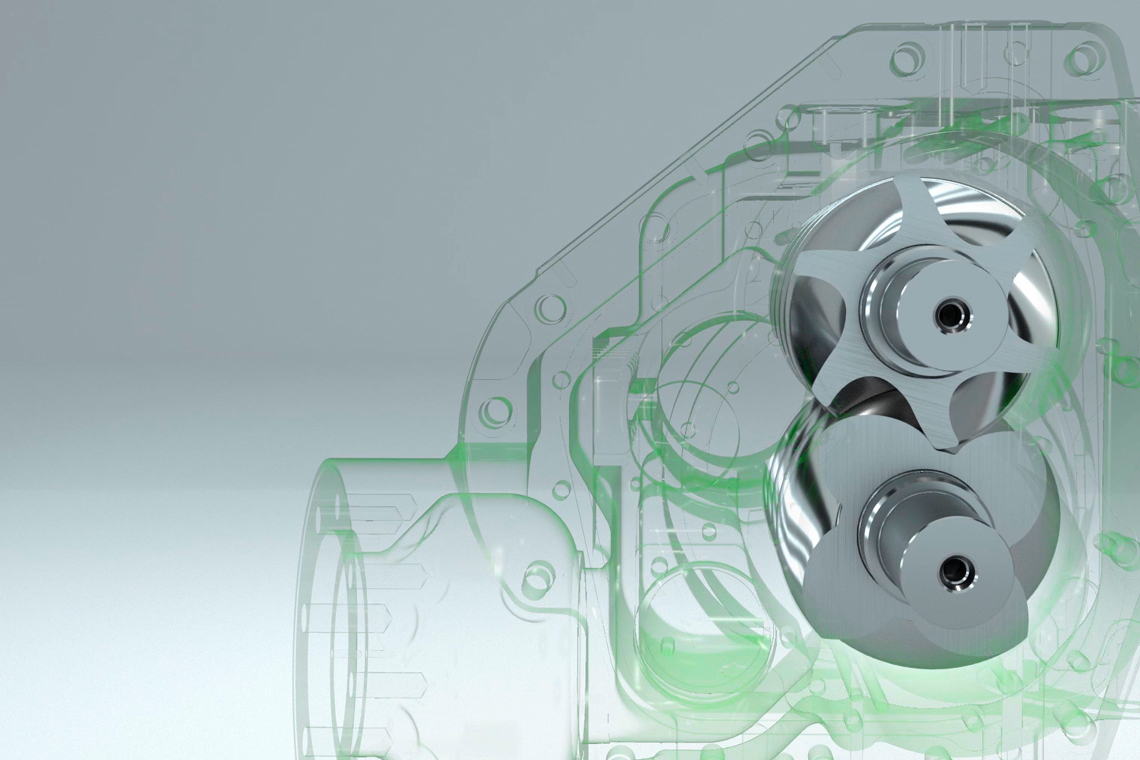

BIPROS is a universal system and focuses on the entire production process as well as the working processes and qualifications of personnel at the same time. The purpose of BIPROS is to guarantee quality, lower costs and accelerate processes. Starting in 2004, the system has gradually been put in place at all BITZER sites. With the safe, standardised and optimised working processes, customers can count on all BITZER products meeting the same strict quality standards regardless of where they were manufactured.

The BIPROS production philosophy consists of five elements: teamwork, just-in-time processes, standardisation, process stability and a continuous improvement process. Additionally, BIPROS is based on pull production with consistent just-in-time delivery. This means that products are only manufactured and assembled once they have been ordered by customers. As such, every compressor is designed in line with the requirements of the customer from the outset and is manufactured to meet their specifications.

Total Productive Maintenance at BITZER

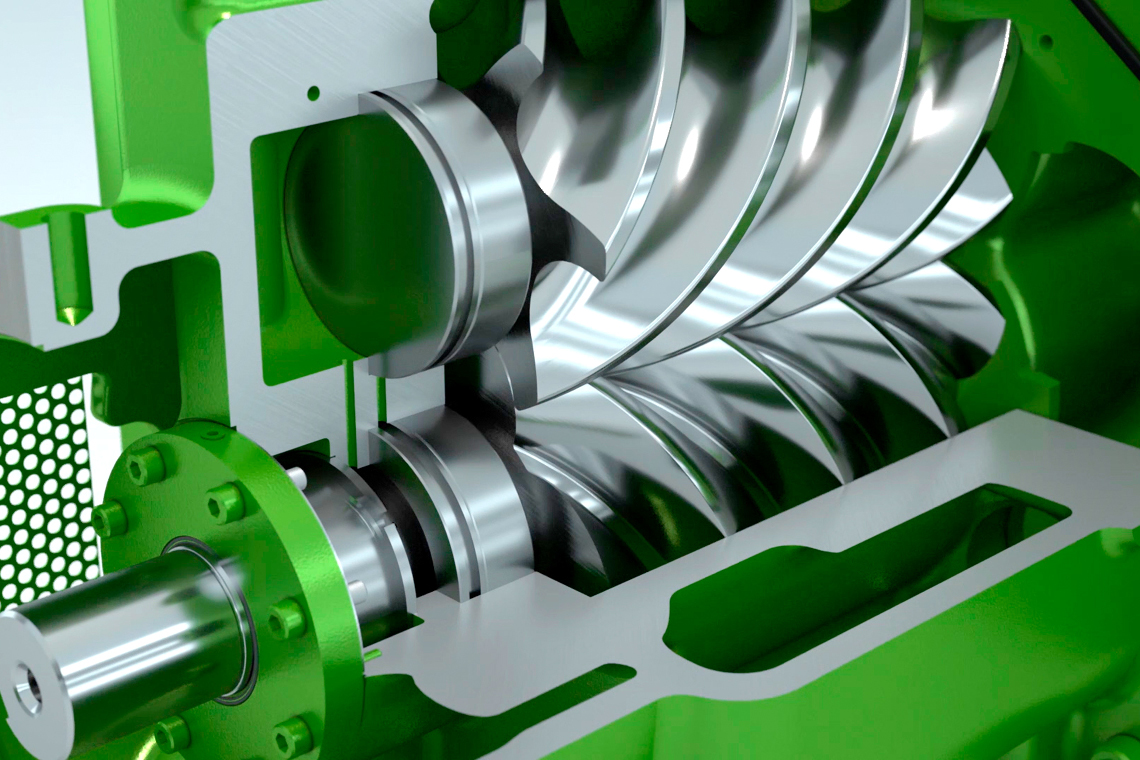

Total Productive Maintenance (TPM) is a key element of BIPROS. The concept helps make the production process as lean, efficient and stable as possible. With TPM, a team of BIPROS specialists at BITZER inspects the production processes, analyses potential for optimisation and prepares specific proposed improvements and key figures for every individual machine on a regular basis. The core team – consisting of mechanical production, maintenance and process development – then gradually implements those parameters for every machine. For example, one measure is that the machine operator is also responsible for maintaining their system. Maintenance personnel are in charge of repairs instead. BITZER is creating simple, stable processes and ensuring high-quality just-in-time production.

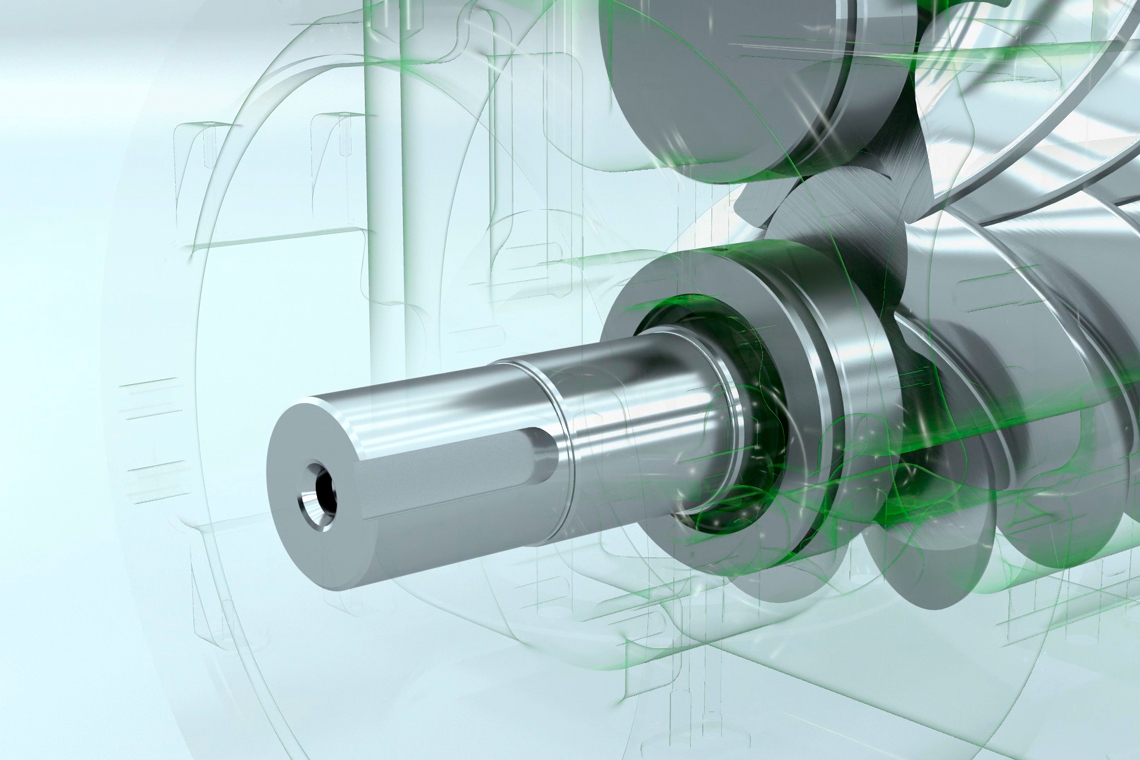

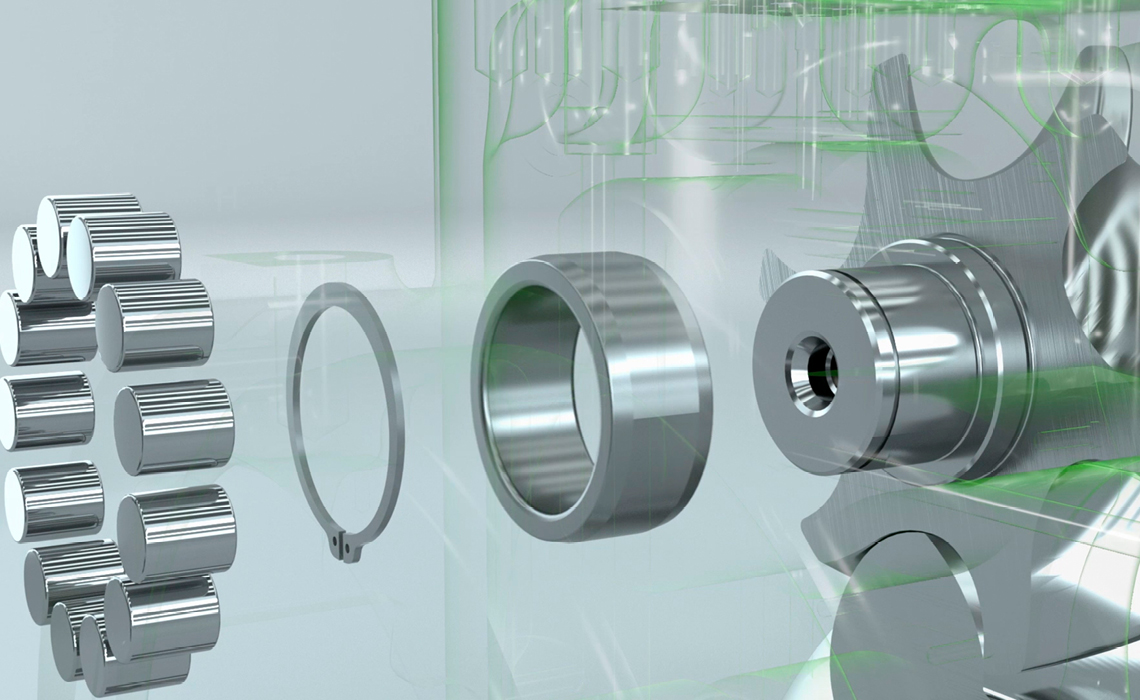

The strategy pays off in light of the wide range of products of the long-standing company and assures the high quality of the products. ‘We manufacture all of the strategically important components of the compressors ourselves’, says Christian Wehrle, member of the Management Board and Chief Operations Officer at BITZER. ‘And when we do purchase components, we purchase them exclusively from partners whose capabilities are very well known to us. Ultimately, “made by BITZER” stands for the highest standards of quality worldwide.’

In the markets, for the markets

Far from uniform throughout the world, the statutory environmental protection regulations that apply to refrigeration and air conditioning technology represent another challenge. This applies to drivers of innovation in the field of green technology such as BITZER in particular. The refrigeration and air conditioning technology specialist has long since established itself as a global player and has been manufacturing all over the world for a number of years. This means that the company has to compile the individual national regulations into a globally functional product development and supply chain strategy in order to provide its customers with the highest standards at all times and in any country.

‘To be there in the markets, for the markets is a key aspect of our success strategy’, says Rainer Große-Kracht, member of the Management Board and Chief Technology Officer at BITZER. ‘Just like the legal standards, the requirements of customers all over the world are highly varied. For example, the climate has a decisive effect on the efficient use of refrigeration and air conditioning technology. By holding a direct dialogue with local users and partners, we know exactly what expectations our products have to meet.’ Thanks to the uniform standards in its production network, BITZER is able to implement it globally and at short notice.

Working with the best: BITZER and its suppliers

‘BITZER quality standards are always a significant challenge for our production sites and for our suppliers. But if we want to guarantee that our products will perform excellently, there are extremely narrow qualitative tolerances that every single component has to meet. Ultimately, our customers rely on the high standards of BITZER products’, says Christian Wehrle. ‘That is why where BITZER is concerned, the production standards are the benchmark of the industry.’